Glass expert performs a failure analysis on a broken drinking glass from a restaurant. As the glass was being filled with cold water, the drinking glass split into two equal halves. The failed drinking glass was made of thick glass, and its rim was tempered. A failure analysis was performed by a glass failure analysis expert, and he discovered that the failure had initiated at a minor damage site on the interior wall of the tumbler. It is hypothesized that the failure was caused by thermal shock. The cold water was poured into a glass recently removed from the dish washer; in this case, the glass had not cooled sufficiently before the interior wall was chilled by the cold water. The cold water rapidly cooled the interior wall and put it into tension. The tensile stresses caused by surface chilling caused the glass to crack. The damage on the interior is believed to have been caused by normal restaurant handling. Tumblers made from thicker glass cool more slowly, and these are more likely to exhibit this type of failure during rush periods in a restaurant. Curiously, this particular glass split perfectly in half.

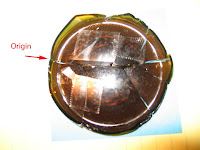

The upper left photograph is an overview of the failed glass. Upper right is a 40X photomicrograph of 1/2 of the failure origin.

Labels: failure analysis, failure analysis expert, failure analysis expert witness, glass expert, Glass Failure Analysis Expert Witness