California Glass Expert Performs a Failure Analysis of Sparkling Liquor Bottle Failures

Labels: bottle failure, bottle failures, California glass expert, glass expert, glass failure analysis, manufacturing defect

READ CONSULTING provides services to industry in the areas of failure analysis, process development and process improvement. Read Consulting is prepared to use its experience and expertise to analyze customers' specific problems.

Labels: bottle failure, bottle failures, California glass expert, glass expert, glass failure analysis, manufacturing defect

The

gas in champagne and most other sparkling wines results from the addition of

a small amount of sugar after fermentation has ended. After the sugar addition,

bottle is capped. The sugar reacts with remnant yeast and converts to alcohol

and carbon dioxide. Because the bottle is sealed, the CO2 gas enters the wine

as a dissolved gas. The conversion of the sugar leaves residue particles in the

wine that make it cloudy. When the sugar was added a small amount of clay

was also added. The clay combines with the fermentation residue and help

with precipitation (i.e. drag it out of solution). In a process called "riddling" the particles are

encouraged to deposit in the bottle neck just under the cap. This deposit forms

a plug that is then frozen and removed before the bottle is corked.

The

gas in champagne and most other sparkling wines results from the addition of

a small amount of sugar after fermentation has ended. After the sugar addition,

bottle is capped. The sugar reacts with remnant yeast and converts to alcohol

and carbon dioxide. Because the bottle is sealed, the CO2 gas enters the wine

as a dissolved gas. The conversion of the sugar leaves residue particles in the

wine that make it cloudy. When the sugar was added a small amount of clay

was also added. The clay combines with the fermentation residue and help

with precipitation (i.e. drag it out of solution). In a process called "riddling" the particles are

encouraged to deposit in the bottle neck just under the cap. This deposit forms

a plug that is then frozen and removed before the bottle is corked.Labels: glass experts, manufacturing defect, wine bottling experts

Labels: glass experts, low-E, manufacturing defect, Product Liability, window defect

Read Consulting failure analysis lab was asked to determine the cause of failure of a small glass cosmetic bottle that had failed in on the filling line as the cap was being tightened. A glass failure analysis was performed using a low power microscope. The root cause of the failure was a chill check on the bottle neck. This damage occurred during bottle manufacturing. The bottling company will work with the bottle manufacturer to eliminate this manufacturing defect.

Read Consulting failure analysis lab was asked to determine the cause of failure of a small glass cosmetic bottle that had failed in on the filling line as the cap was being tightened. A glass failure analysis was performed using a low power microscope. The root cause of the failure was a chill check on the bottle neck. This damage occurred during bottle manufacturing. The bottling company will work with the bottle manufacturer to eliminate this manufacturing defect.Labels: failure analysis lab, glass expert, glass failure analysis, manufacturing defect

|

| Overview of Assembled Bottle 8X Mag. |

|

| View of Origin on Bottle 40X Mag. |

|

| View of Origin on Neck 40X Mag. |

Labels: California glass expert, glass failure analysis, manufacturing defect, Product Liability

Labels: manufacturing defect, metal failure analysis, metal fatigue, northern california failure analysis expert

Labels: failure analysis, glass cookware, manufacturing defect, Product defect, visions cookware

A failure analysis was performed on a toilet tank that had caused water damage to a residence. This failure initiated at a hold down bolt hole. This tank was 14 years old. Originally it was proposed that thus porcelain failure was the result of a manufacturing defect. The root cause failure analysis shows that the tank was subjected to forces that were transfered to the porcelain through the hold down bolts. This toilet tank failed as a result of undue forces. It is not the result of a product defect.

A failure analysis was performed on a toilet tank that had caused water damage to a residence. This failure initiated at a hold down bolt hole. This tank was 14 years old. Originally it was proposed that thus porcelain failure was the result of a manufacturing defect. The root cause failure analysis shows that the tank was subjected to forces that were transfered to the porcelain through the hold down bolts. This toilet tank failed as a result of undue forces. It is not the result of a product defect. Labels: failure analysis, manufacturing defect, porcelain toilet tank, Product defect

Labels: california failure analysis expert witness, california glass failure analysis, failure analysis, failure analysis expert, manufacturing defect

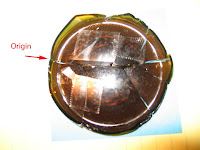

California failure analysis expert witness was asked to perform a detailed failure analysis of a broken wine bottle. Glass fractography was used to determine the root cause failure mode. The failure originated at damage caused by the prop on the cork screw. The fact that there were two damage sites on opposite sides of the bottle and that the cork was only partially removed, indicates that the force to remove the cork was excessive. The donward force on the prongs crushed the top of the bottle at two places and initiated a crack that was driven by the force needed to move the cork. This failure was not the result of a bottle manufacturing defect; it was caused by the high forces needed to move the cork and the type of cork screw used. Upper left is a photograph of the two pieces of the bottle neck. Upper right is a 20X photomicrograph of the failure origin and the initial part of the crack. The arrows show the initial travel direction of the crack. Also, visible is the "crush point" at the beginning of the failure.

California failure analysis expert witness was asked to perform a detailed failure analysis of a broken wine bottle. Glass fractography was used to determine the root cause failure mode. The failure originated at damage caused by the prop on the cork screw. The fact that there were two damage sites on opposite sides of the bottle and that the cork was only partially removed, indicates that the force to remove the cork was excessive. The donward force on the prongs crushed the top of the bottle at two places and initiated a crack that was driven by the force needed to move the cork. This failure was not the result of a bottle manufacturing defect; it was caused by the high forces needed to move the cork and the type of cork screw used. Upper left is a photograph of the two pieces of the bottle neck. Upper right is a 20X photomicrograph of the failure origin and the initial part of the crack. The arrows show the initial travel direction of the crack. Also, visible is the "crush point" at the beginning of the failure. Labels: bottle failure, bottle failure analysis, California glass expert, failure analysis expert, fractography, glass fractography, manufacturing defect, root cause failure analysis

California failure analysis expert uses glass fractography to perform a glass failure analysis on a tempered glass window failure. The glass fracture analysis showed that the window failure was a result of heating the glass in the center. Due to the heat, the center of the window expanded. This created additional tensile stress on the window edges. Although the window edge was ground and chamfered, there was enough residual damage at the edge that the thermal stresses were able to cause window failure. Upper left shows the failure initiation site on the edge of the window. Upper right is a 40X photo micrograph of the origin on one of the fracture surfaces. The glass fracture analysis showed that the glass failure initiated on the window's edge face and propogated inward until the tensile center of the tempered glass window was reached. At this point the residual tempering stresses caused the entire window to self destruct into small "cubic" pieces. This may be a manufacturing defect because of the severity of the edge damage.

California failure analysis expert uses glass fractography to perform a glass failure analysis on a tempered glass window failure. The glass fracture analysis showed that the window failure was a result of heating the glass in the center. Due to the heat, the center of the window expanded. This created additional tensile stress on the window edges. Although the window edge was ground and chamfered, there was enough residual damage at the edge that the thermal stresses were able to cause window failure. Upper left shows the failure initiation site on the edge of the window. Upper right is a 40X photo micrograph of the origin on one of the fracture surfaces. The glass fracture analysis showed that the glass failure initiated on the window's edge face and propogated inward until the tensile center of the tempered glass window was reached. At this point the residual tempering stresses caused the entire window to self destruct into small "cubic" pieces. This may be a manufacturing defect because of the severity of the edge damage. Labels: failure analysis, failure analysis expert, fractography, Glass failure expert window failure, glass fractography, glass fracture analysis, manufacturing defect, tempered glass window failure

Labels: design defect, failure analysis, fatigue failure, manufacturing defect, plastic failure analysis, plastic failure analysis expert, Product liabilityt

Labels: failure analysis, Glass Failure Analysis Expert Witness, manufacturing defect

Labels: failure analysis, failure analysis expert, failure analysis expert witness, glass failure analysis expert, manufacturing defect, nickel sulfide, NiS particle

Labels: california glass failure analysis, failure analysis, failure analysis expert, failure analysis expert witness, manufacturing defect

Labels: failure analysis, failure analysis expert, failure analysis expert witness, glass failure analysis expert, manufacturing defect, window damage, window scratches, window scratching

A glass failure expert witness performs a failure analysis on a failed cosmetic bottle. As received, the top of the bottle had broken off. Upper left is a photograph of 'as receceived' failed bottle. Approximately one half of the bottle finish had broken off. Read Consulting performed a glass failure analysis to determine if this failure was a manufacturing defect, or it failed as a result of shipping damage. The upper right photomicrograph is 30X view of the failure origin. The failure initiated at a bruise (small impact damage) on the top of the finish. Three of nine bottles from the same molding cavity also had damage to the top of the finish. In this shipping lot there were over thirty five bottles from other cavities, and none of these showed damage. Thus, the glass failure analysis expert witness believes that this product defect occured during manufacturing. However, both the shipping methods and the manufacturing proceedures will be reviewed for product liability improvement.

A glass failure expert witness performs a failure analysis on a failed cosmetic bottle. As received, the top of the bottle had broken off. Upper left is a photograph of 'as receceived' failed bottle. Approximately one half of the bottle finish had broken off. Read Consulting performed a glass failure analysis to determine if this failure was a manufacturing defect, or it failed as a result of shipping damage. The upper right photomicrograph is 30X view of the failure origin. The failure initiated at a bruise (small impact damage) on the top of the finish. Three of nine bottles from the same molding cavity also had damage to the top of the finish. In this shipping lot there were over thirty five bottles from other cavities, and none of these showed damage. Thus, the glass failure analysis expert witness believes that this product defect occured during manufacturing. However, both the shipping methods and the manufacturing proceedures will be reviewed for product liability improvement.

Labels: glass expert, Glass Failure Analysis Expert Witness, manufacturing defect, Product defect, Product Liability

Glass failure analysis expert witness discusses a common glass bottle manufacturing defect. After the bottle has been formed it is removed hot from the clam shell tool. If it encounters any localized cooling at this stage, it can form a manufacturing defect called a "chill crack". Thermal shock cause the cooled area to shrink, and this causes localized tensile stresses. This event can create a small crack that can cause later failure of the bottle. Above are two photos of the same chill crack. Upper left is a 20X photomicrograph, and upper right is a 40X photomicrograph. To start, this crack is less than 0.1" long, and it has grown to be approximately 0.7" long. The bottling line has had numerous failures from this lot of bottles, and the cause has been traced back to this type of chill crack.

Labels: failure analysis expert, failure analysis expert witness, glass expert, glass failure analysis expert, Glass Failure Analysis Expert Witness, manufacturing defect

Glass failure analysis expert witness performs failure analysis on a broken small cosmetic bottle. This bottle failure occured when it was being capped on the line. The objective of the analysis was to determine the cause of the failure and to advise the bottle manufacturer. The bottle broke into two pieces, and these are shown in the upper left photograph. Upper right is a 20X photomicrograph of the failure origin. This failure originated as a result of a "chill crack" which is a manufacturing defect formed when, exiting the clam shell tool, the hot bottle touched an unprotected metal tool. The cold spot created a chill crack that eventually caused the bottle failure. The manufacturer is presently correcting the manufacturing problem. In the meantime, only bottles from another supplier are being used.

Glass failure analysis expert witness performs failure analysis on a broken small cosmetic bottle. This bottle failure occured when it was being capped on the line. The objective of the analysis was to determine the cause of the failure and to advise the bottle manufacturer. The bottle broke into two pieces, and these are shown in the upper left photograph. Upper right is a 20X photomicrograph of the failure origin. This failure originated as a result of a "chill crack" which is a manufacturing defect formed when, exiting the clam shell tool, the hot bottle touched an unprotected metal tool. The cold spot created a chill crack that eventually caused the bottle failure. The manufacturer is presently correcting the manufacturing problem. In the meantime, only bottles from another supplier are being used.Labels: bottle failure analysis, failure analysis, failure analysis expert witness, Glass Failure Analysis Expert Witness, manufacturing defect

Labels: bottle failures, failure analysis, glass failure analysis, Glass failure expert, manufacturing, manufacturing defect, Product Liability